December 2022 Stats

New Projects

Completed Projects

Work In Progress

Happy New Year.

We’re back in the office, and December seems a bit of a distant memory following our festive break. It was a shorter month but a busy one nonetheless. Our work included the following:

- A bespoke high-pressure connection device

- Ornamental decorations for public areas

- An orthopaedic implant

- Design updates for a consumer product

- Bespoke packaging solutions for multiple products

Thank you for your support, and we look forward to another successful year of working together and innovative designs.

Using Global Variables to define parts and leverage data

If you have been using SolidWorks for a while, you would have most likely come across Global Variables. But you may not realise how useful these can be.

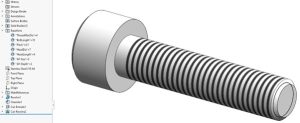

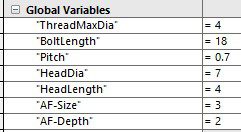

We have created a series of ‘standard’ parts from a model we created using Global Variables.

By breaking down the features of a part into a series of Global Variables and equations, we can create a family of similar parts quickly and efficiently. These variables will bring very little to the party if just a part is needed. However, if you want your part to be truly useful in an assembly, and you want to eliminate errors caused by customer fields not being updated, I think Global Variables are a game changer.

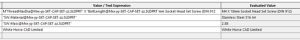

Not many people realise that Global Variables can be used in custom properties. With some care, you can use more than one in the same data field. For example, the description of the cap head screw above is generated from a mixture of Global Variables and text. If the size changes, the description automatically updates so you know your M4 x 18 Socket screw head is M4 and 18mm long. When you build your Bill Of Materials in your assembly files, you can be confident that the fasteners are correctly specified. As this is not a toolbox component, it will always be available to all versions of SolidWorks, not just those licences for the Premium and Professional versions.

To download our fastener file click here.

Long-term advantages of using 3D CAD over 2D CAD

An efficient business is something we’re all striving for. As we start the New Year, we think it’s good timing to think beyond the short-term wins and consider the long-term benefits of moving from traditional 2D CAD to 3D CAD. This is especially true if you have a product with a variable. For example, longer, taller, thicker, more holes and fewer holes.

Firstly, 3D CAD gives us parametrically configurable data. This means a whole family of products can be created from a single CAD model. Although CAD models of this nature can take a little longer to create, which may increase the initial cost, the ongoing costs to make design variations (rather than starting from scratch each time) are much lower.

The 2D and 3D manufacturing data can be directly output from the CAD models. From flat patterns for laser cutting to solid part files for programming CNC machines, making the manufacturing process more efficient. It’s a money saver for CAD data and manufacturing.

Product Visualisation is also a significant benefit of adopting 3D CAD over 2D CAD. 2D CAD drawings can be complex and disengaging for those without the technical knowledge to understand them properly. Engineering drawings can overwhelm the un-trained person; very few people can imagine a complex 2D object from a series of 2D drawings. 3D models are, by comparison, easier to understand and can be easily shared with clients or critical decision-makers. These 3D models can bring ideas and concepts to life.

3D CAD also is beneficial for marketing purposes. Some products are difficult to photograph, and some are difficult to assemble or maintain. This can be overcome by using the 3D CAD data for things like promotional images, instruction manuals, or even interactive “how to” animations. This gives you and your clients, investors, and service personnel a much deeper understanding of how the product looks, how it fits together and how its maintained, even before a part is manufactured.

Please get in touch to discuss our 3D CAD services on 01373 801 803.

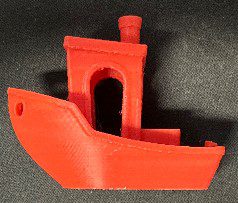

Soapbox carts are go!

Using the latest CAD software, we’ve created model soapbox carts to help local students build and design their own carts.

Using the latest CAD software, we’ve created model soapbox carts to help local students build and design their own carts.

We printed the large scale drawings of the models for them to use at workshops to outline their plans and understand the professional process of developing a concept on paper to construction of the soapbox. We look forward to seeing their entry complete in the Westbury Soapbox Derby on Saturday 20 May 2023!

You must be logged in to post a comment.