October 2023 Stats

New Projects

Completed Projects

Work In Progress

Welcome to our November update. The past month has been full steam ahead working on some exciting projects. Due to our confidential agreements, we can’t reveal too much, but here’s some insight into recent jobs. We hope these give some food for thought…

- Bespoke protective packaging

- Drawing updates for an electronic company

- Floor plans for a local health authority (more on that below)

- Providing expertise in a design review for a medical device

- Reverse engineering and 3D scan of an obsolete part

On the latter point, a 3D scan can be necessary for obsolete parts, particularly when time is of the essence to get a replacement. Read on to find out more about 3D Scanning, the common myths and the truth behind them.

3D Scanning Myth Busting

3D Scanning is a relatively new tool in the engineering arena. Although the technology is still in its infancy, it has come a ling over the past decade. It is a handy toll for reverse engineering parts that are difficult or impossible to measure. 3D Scanning can also create full-colour 3D assets for websites or presentations.

3d Scanning produces CAD data – Myth

People often think the output of a 3D scanner is a full defined CAD file to create 2D and 3D manufacturing data. However, this is not the case. 3D sanners output mesh data or point clouds, which you can import onto CAD software as a 3D graphical file or mesh. They do not output defined CAD data with flat surfaces, defined curves, or exact angles. Although, the data output can be a helpful tool to help guide the reverse engineering of complex geometries.

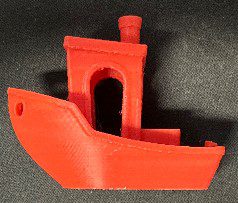

Original 3D Print

Looking closely at the Red Benchy, the corners on the ledges and door frame are crisper and sharper compared to the Green Benchy. There is a loss of definition of these sharp corners, which would be even less if scanned further.

3D Print from 3D Scan

The green one has no details inside the wheelhouse because the 3D Scannercannot see inside the wheelhouse. Therefore, the software fills in the missing information to make the 3D scan watertight mesh.

Everything can be 3D Scanned = Myth

Nearly everything can be 3D scanned, but the results of some scans will depend on more than the shape. People 3D scan houses, cars, planes, tanks, or anything else! However, it gives a skewed outlook on the capability of the technology. These tell us big things are scannable, but the level of detail is low.

Anything smaller than a 30mm x 30mm x 30mm cube, is difficult to scan. It is impossible to scan small items on most medium to high-end 3D Scanners; it requires specialist technology.

Regarding colours, 3D scanners can see them all however black or reflective items are less likely to yield good scanning results. Some coatings can improve the results, but these add more cost and health and safety concerns.

3D Scanning is cheap = Myth

We very rarely must justify the costs for 3D Scanning parts. It’s not necessarily the scan itself but the equipment and time associated with the scanning process that surprises people with 3D Scanning quotes. For example, to provide this service, we

- Own a 3D Scanner (£2000+)

- Are trained in 3D Scanning

- Have a computer dedicated to 3D scanning use (£1500+)

- Have space to house and use the 3D Scanner

- Incorporate associated business costs such as wages and electricity to do 3D Scanning in our office.

The 3D Scanning process is:

- Set the equipment up.

- Calibrate the Scanner before each use.

- Scan the part.

- Clean the equipment and then store it away.

- Edit and process the Scanned data.

- Save the 3D scan in a usable format.

Although a straightforward scan can take from 10 minutes to complete, in all, the above process takes at least 30 minutes. Therefore, we quote from £40 to 3D scan the part with editing or 3D print at an additional charge. It’s fair to say, 3D Scanning is not cheap, it’s cost-effective.

To conclude, 3D Scanning is a helpful technology and an invaluable tool to help reverse engineer complex geometry. You will be hard-pushed to find a better, cost-effective solution to copy simple obsolete parts. However, as addressed, there are limitations to be aware of.

|

We’re working with a local health authority to help update their Fire Safety Plan. Following a site visit, we create accurate floor plans showing the new rooms, exits, etc. These can be printed up to A1 by our in-house printer, making visualisation easier.

We’re working with a local health authority to help update their Fire Safety Plan. Following a site visit, we create accurate floor plans showing the new rooms, exits, etc. These can be printed up to A1 by our in-house printer, making visualisation easier.

We are happy to share, we are again sponsoring our local football club, Westbury United and wish them all the best for this season.

We are happy to share, we are again sponsoring our local football club, Westbury United and wish them all the best for this season.

You must be logged in to post a comment.