Client: Planet Lighting Limited

Project: EyePower Red Glasses

Customer Requirements

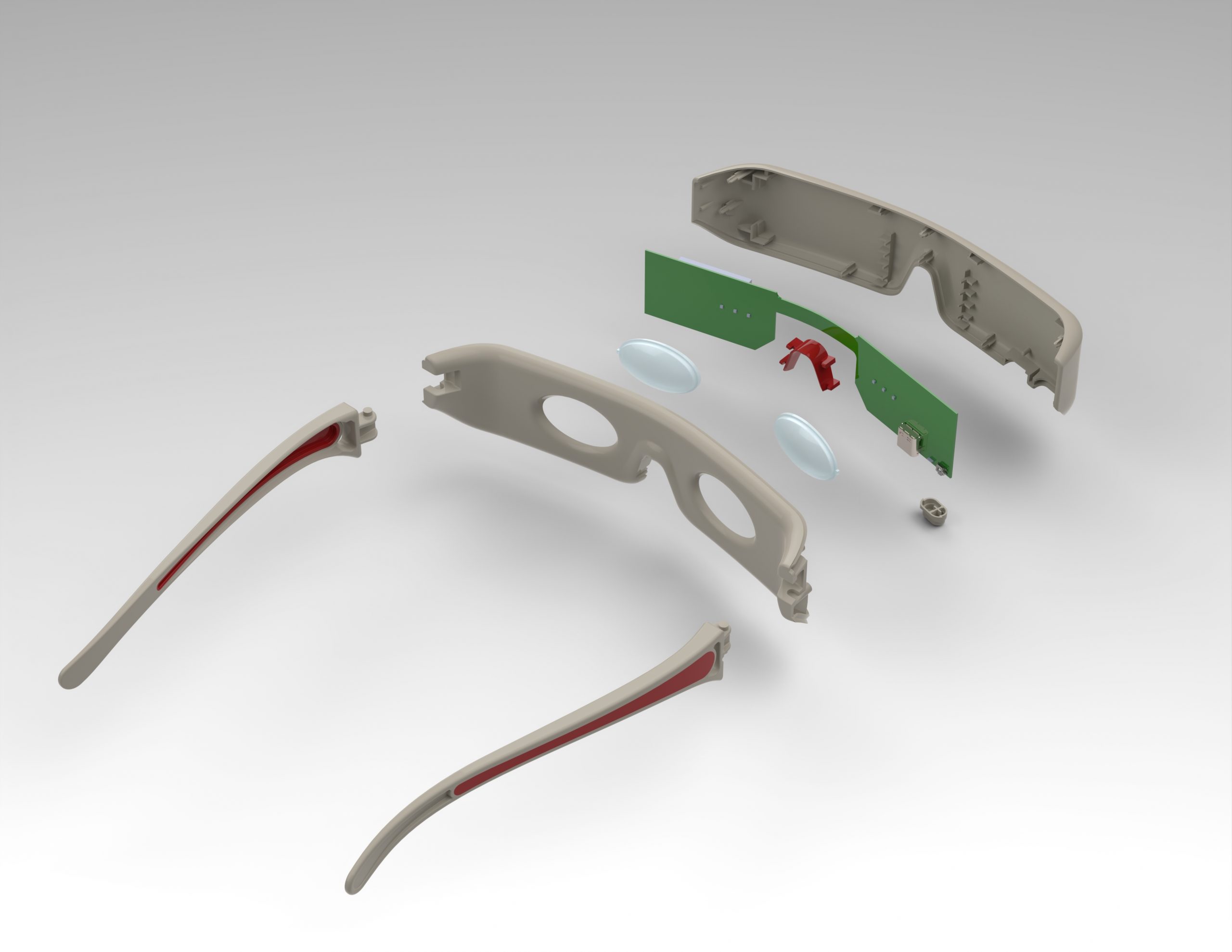

EyePower contacted White Horse CAD to seek advice on modifying the body of their innovative eyewear, which employs electronics to improve eye health.

How we helped

We worked with existing CAD data to modify the geometry, making the concept design suitable for injection moulding. The concept had been tried and tested using 3D prints. We were careful only to modify features that would not affect the aesthetics of the design or the internal connections with the electronic components.

Some internal features needed to be modified to ensure suitable draft angles for injection moulding. This also eliminated any geometry that was not suitable for the process. The CAD files we received were not native SolidWorks data, but we were able to modify the underlying geometry using advanced modelling techniques.

Deliverables

- 3D files for manufacture

- 3D CAD data (STEP & Parasolid) for each injection moulded part and over-moulded assembly.

Planet Lighting Testimonial

“Having spent many months with two other CAD designers on a new product concept I was losing confidence in their ability to resolve manufacturing issues. I approached Tim at Whitehorse CAD to ascertain whether his company was up to the job.

Within a few minutes, I realised I had made the right choice. Not only did Tim reassure me that all the outstanding issues could be solved relatively easily, he also identified a bunch of other issues that previous designers had missed. Once completed, he then liaised with the injection mould tool engineers to ensure everything would go smoothly in production.

It is no exaggeration to say that without Tim’s input the final manufactured product would have been seriously inferior to the one he has delivered. When it comes to future product designs Tim will be our man!”

If you would like to discuss a project, please contact us.

You must be logged in to post a comment.